Being one of the biggest beneficiaries of the construction and development activities in the country, especially since election is round the corner, no one can blame the cement sector for being complacent. Companies have been racing to announce their own capacity expansions since 2016 with capacity utilisation continuing to hit the ceiling. In fact, just last month, it reached the under capacity phase, crossing 100 percent monthly utilisation then, and again in April.

There isn’t anything new to write about on the flourishing local demand. Demand outside Pakistan however is difficult to pin down. Exports to Afghanistan have been seeing upward spikes for a few months now, though as stated earlier, it would be premature to call it a “turnaround”.

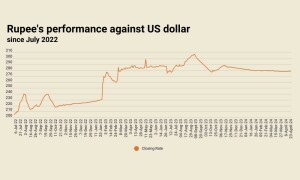

While growth offers an optimistic perspective, the picture skews when we consider the dual effect of coal prices going up globally, and the rupee depreciating against the dollar. Both these factors have pushed up cost of production for manufacturers significantly. This resulted in margins for cement manufacturers dropping by an average of 10-12 percent for prominent players in 9MFY18, and a decline of 21 percent in the bottom-line in the last quarter of the fiscal.

Another factor to look at is the retention prices which have fluctuated quite significantly over the past two years. They averaged at Rs551 per a 50-kg bag in Jan-17 but as capacity utilisation maximized, they had dropped to Rs544 in April-17. Prices further declined as new plant expansion for Cherat came through that resulted in an overcapacity of sorts. By Feb-18, prices on average had fallen to Rs521 per bag. However, things took a round turn as manufacturers began to raise prices starting March.

Many of the expansion in the north were put to a halt by order of the Supreme Court during the Katas Raj case. Environmental concerns in the region pushed regulators in action. Expansions delays allowed the sector to raise prices. Average cement prices increased to Rs553 per bag in Apr-18 with price hikes initiated by most cement plants in the north.

Prices for players in the south have historically remained high and consistent—the fluctuations come from the north as it is the driver of demand and capacity. With the budget kicking off from July1, the new FED on cement will be Rs1.5 per kg essentially making FED on each bag to be Rs75 against Rs62.5 last year. When this happened in the previous budget, manufactures raised consumer prices and same is expected this year.

On the exports front, none of the markets are going to be receptive going forward. South African imports from Pakistan have dwindled in light of the anti-dumping duty in place; while exports to India have also declined owing to that country’s increase in capacity and falling prices. Pakistani exports were only attractive because they were 15 percent cheaper. If Indian manufacturers keep prices competitive, it doesn’t paint a very export-friendly picture for Pakistan.

The biggest export market for Pakistan has been Afghanistan. In fact, Pakistan, Iran and Tajikistan together export 10,000 tons of cement every day to the nation while its own capacity is less than 1000 tons per day. Iran’s influence grew as sanctions were removed and it usurped a significant chunk of the market that Pakistan was catering to with its less costly cement. This resulted in a sharp decline in Pakistani exports since 2016.

During the current fiscal, exports to Afghanistan have witnessed a slow burning growth. Monthly average so far is around 160,000 tons while it was 149,000 tons last year. A quick calculation would suggest Pakistan still caters to more than 50 percent of the Afghani cement demand. Only time will tell whether the current growth is a meaningful trend. The country is set to produce more of its own cement and cut down its imports.

The Ministry of Mines and Petroleum (MoMP) in Afghanistan is reissuing a tender for a cement factory which will produce a million tons annually. This would equate to 30 percent of the country’s current imports.

Given Iran’s cheaper cement, and other Central Asian players also vying to enter the Afghan market, Pakistani cement might get displaced further. On the other hand, if US sanctions to Iran play out, it could affect the country’s exports. For Pakistan, gaining market access into Afghanistan is a toss-up at this point.

The question is whether exports are really a major concern. The sector is hovering on over capacity and local demand is poised to capture much of the new capacity that will come through in the short run. Exports are not the immediate threat; increase in coal prices and the new FED are both to net profitability and end-user cost of construction.

Comments

Comments are closed.