Continuing our conversation on textile machinery imports (see yesterdays column), todays article looks at some underlying issues that have gone unsaid.

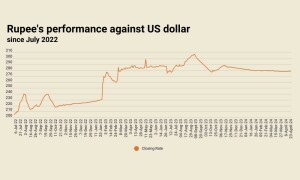

First and foremost, the issue is of affordability. Given todays rapidly changing technology not to mention the gradual devaluation of the Rupee over the years machinery now costs more than it did before. Low availability of credit to the private sector makes it difficult to undertake such costly investments. Moreover, most exporters are already facing liquidity issues due to pending refunds from the government. Thus, the emphasis of our industry is and always has been short term (Read: Innovation and productivity: thinking beyond costs, published January 10, 2017).

Secondly, more machinery means a higher energy requirement. The government needs to start speedy facilitations for new industry connections. According to the World Banks Doing Business index, Pakistans DB rank for 2017 in the Getting Electricity factor has fallen by seven places to 170 the largest decline year-on-year among the ten indicators, and the second-worst of all (after Trading across Borders, ranked 172).

Thirdly, higher energy requirements mean that tariffs would also need revision. Indeed, one of the key points that the export package didnt address was bringing down the energy tariff, which is the highest in Pakistan among its south Asian competitors and one of the key bones of contention between the industry and the establishment.

We also know that there are no major domestic manufacturers of textile machinery. An industry source told BR Research that by and large (roughly 80 percent), machinery in Pakistan is imported. This machinery is also cost-efficient and consumes low electricity. So, imports will do just fine, and the removal of taxes and duties on this machinery is a very welcome move. But the above structural issues would need to be addressed in order for the imports to really take off.

BR Research spoke to former KCCI President Majyd Aziz, who suggests that the government should go one step further and encourage the import of new machinery rather than old. There should be some advantages or attractions for those individuals that import brand new machinery rather than used. Machinery, after all, is a one-time expense; it increases capacity, production, and productivity, and should not be compromised.

Comments

Comments are closed.